A Catrike Trail E-Cat accessorized with a Shimano Alfine-8 drivetrain upgrade, Racktime rear rack with integrating basket, phone-mount, and extra mirror using AlphaBENT accessory mounts.

You are here

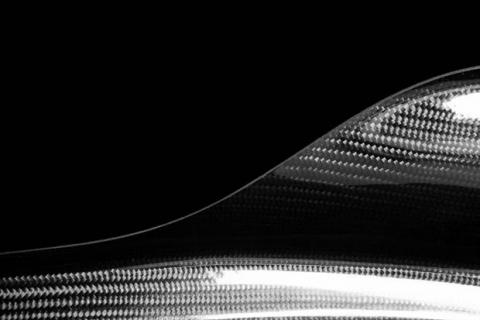

ICE Air-Pro carbon fiber seat

Inspired Cycle Engineering is reknowned for blending comfort and efficiency in their hardshell carbon-fiber seat for the speedster VTX model.

In this series of time-lapse videos, you get to see the workmanship, engineering, and skill that goes into the backbone of the AirPro carbon fiber seat. In their own words,

The ICE Air-Pro Carbon seats are handmade composite hard-shell seats that provide exceptional stiffness with minimal weight, weighing in between 1.1-1.4kg with the carbon saving approx 0.38Kg (0.84lbs) over the GRP version. The Air-Pro shell is an anatomically contoured shape which is available in two sizes (medium & large). The shell supports the rider through aggressive cornering and provides a firm brace to pedal against while flexing where appropriate for comfort. The shell has incorporated wings unlike most of its competitors which reduces weight and increases efficiency. Fitted to the shell is a custom composite fabric cover made from carefully selected foams and surface materials for ultimate performance. Max rider weight 230lbs (104Kg). The technical pad system is arranged to provide maximum comfort and support while riding, incorporating natural ventilation channels to maintain a cooling airflow across the back. Recognising that the shape and riding style of every rider is undoubtedly different ICE have also designed a personal padding system that is provided separately, these pads allow the rider to place extra pads directly to the shell and under the cover for added support in areas they deem necessary....

Every ICE Air-Pro Carbon Fibre or GRP seat is designed and fabricated in the UK at ICE HQ, Falmouth. Each seat is made using the highest quality design processes, raw materials and craftsmen. Designed in house using the latest CAD technology, the moulds are CNC routed for precision quality seat after seat. The seat itself is fabricated by a small team of professional and passionate craftsman; each seat is subject to the same reliable method of production within our small controlled environment. The seats are then finished by eye to ensure the highest quality finish time and time again. Each seat takes roughly 4-5 hours to produce from start to finish over several days.

Go to their website. Read all about it. Watch the videos. And, when you feel the need for speed, call us.

Image gallery

Information

A fire in the early morning of 5 June 2024 destroyed our neighbor business, MidCentury Sacramento. AlphaBENT escaped the worst of it and is back up and running.

Classifieds

Azub, Bionx, Catrike, GoSwiss, ICE, HP Velotechnik, Greenspeed

Join AlphaBENT in welcoming HP Velotechnik during their 2017 West Coast Tour.